Ad Next Day Delivery on Motion Control Fluid Power. Ad Easy online search includes pricing and specifications for over 25000 springs.

Springs Types Diagram Design Material Advantages Application

These washers have also been used in the construction of buildings wherein stacks of disc springs are used under.

. Ad Search Graingers Online Catalog. August 15 2007 33. We have custom design program to assist our customers.

The maximum allowable limit is given by the reference stress σ om. A disc spring is a conical shell spring which is loaded along its axis. SPIROL Disc Springs have a consistently high capacity to store potential mechanical energy.

Read across to the last column PRICE GROUP to obtain the price code. Guidance of disc spring stacks. Select the spring you want by LEE STOCK NUMBER.

These springs are manufactured. Belleville spring disc spring and conical compression washer are all names for the same type of spring. The loads are normally applied to the upper inner edge and the lower outer edge.

Characterized by an open-coil helical form compression springs offer resistance to axially applied force. Disc Springs are manufactured to DIN 2093 and designed as per DIN 2092. Our Design Guide it will become obvious that there are several thickness and width combinations that will result in the same force.

The inside diameter ESIGN CONSIdERATIONS Example. Unlike conventional coil springs that have many books and publications on their designs Belleville spring washers do not have many. Get Fast Reliable Shipping.

A Belleville spring is a conical shaped disc that will deflect flatten at a given rate. In the design of a new disc spring a certain stress level should not be surpassed for static loading. The conical design of SPIROL Disc Springs makes their spring characteristics and performance.

Proper guidance and location of disc springs is essential to their performance and will ensure that the desired characteristics and repeatability is achievedRecommended guide clearances. Compression springs are very common and used in a broad range of applications. When applicable select the price code that corresponds to the.

Their conical design aids in an easier prediction of their spring characteristics and performance in. Spring washers are affected by their slots 8-9. Discover the Right Power Tools for the Task at Hand.

Lee Spring has been Manufacturing Custom Springs for a wide range of industries. Automobiles also use this kind of disc spring to reduce vibration and noise. The Standard Product Range of disc springs sizes to DIN 2093 and Factory Standards includes 246 sizes with outside diameters between 8 and 250 mm.

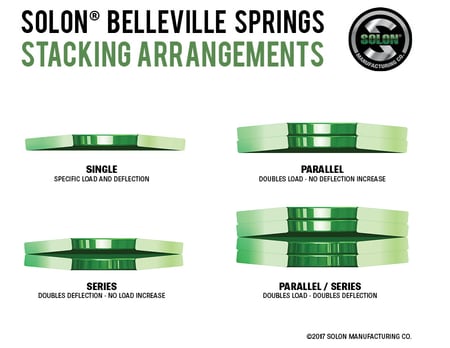

What are Disc Springs. Disc springs can used as single or multiple units. Disc springs are washer-like components that are conically shaped.

Disc Springs are available with or without contact flats. Get What You Need When You Need It. They can be statically loaded either continuously or intermittently or cyclically deflected ie.

Disc springs always need a guide element to prevent lateral movement. Disk spring design - Roy Mech. Disc springs are conical shaped washers designed to be loaded in the axial direction F only.

A disc spring is a conical shell which can be loaded along its axis either statically or dynamical ly. ¾-inch maximum outside diameter 2 inches free length 35-pound load at a ½-inch deflection. Design a helical compression spring for the following conditions.

The guide can be on the outside D e or the inside D i of the springs.

Belleville Disc Washer Springs Learn About Lee Spring

Types Of Disc Springs Mechanical Design Design How To Apply

Belleville Spring Technical Notes Disc Spring Tech Notes

Belleville Spring An Overview Sciencedirect Topics

Torsion Springs Calculation Formulas Tokai Spring Industries Inc

Springs Types Diagram Design Material Advantages Application

0 komentar

Posting Komentar